mission

Innovation and quality serving the customer.

Reliability. We work hard to satisfy our clients. The professional distinction of our collaborators allows us to face any situation.

Time. We aim at satisfying clients quickly with slim production and automated delivery management.

Result. We always try to find the best solution for our clients’ requests and give an excellent result. Our results are the logical consequences of an efficient company, a quality product and attention given to clients.

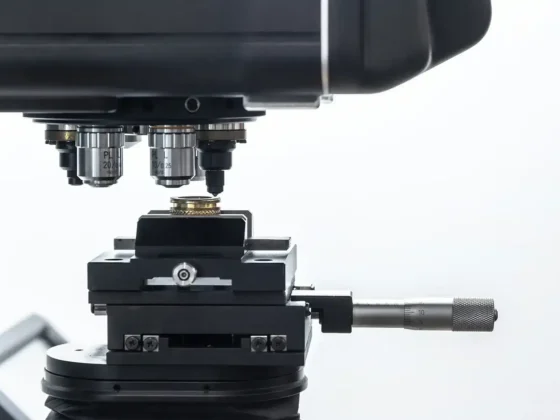

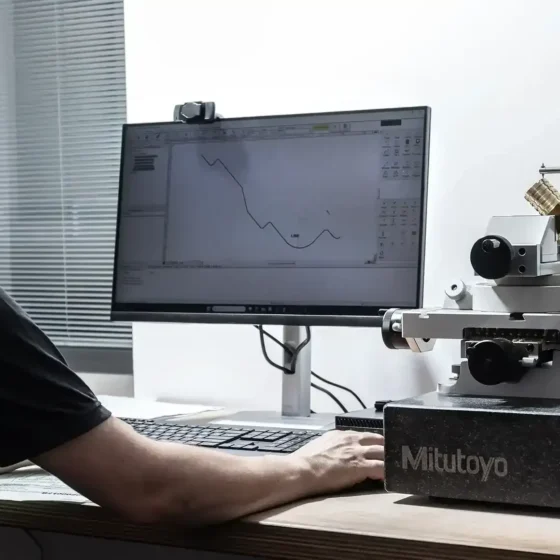

quality

The highly qualified staff uses innovative equipment to inspect all the production process and material supply phases. The staff contributes to managing product traceability, perfecting the processes and products according to the international quality standards, until delivery.

• Acceptance

• Production kick off inspection

• Line inspections

• Downstream wash inspections

• Inspections during packing

certifications

With implementation of its quality system and the chain of production integration processes that follow the product through all its phases, Marangon Danilo & C srl obtained UNI EN ISO 9001 international quality certification in 1998. After this, constant investments and system updating made it possible for the company to obtain UNI EN ISO 9001:2015 certification.

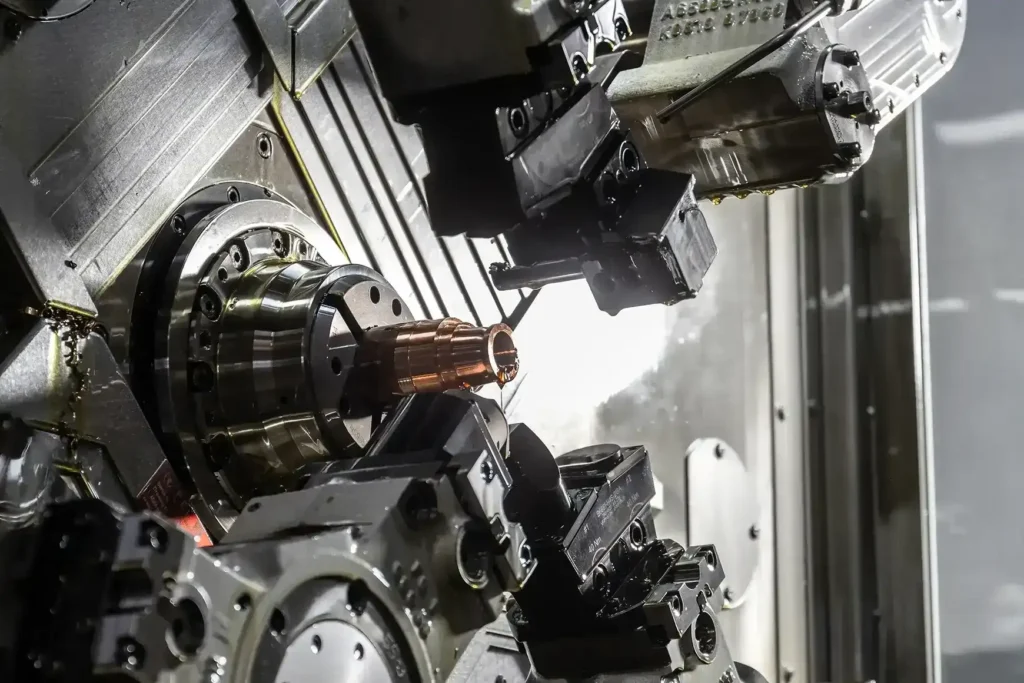

investments

Competitiveness, evolution

Being competitive with a continually developing market pushes Marangon management to make continual investments in research on innovative work processes, machinery that is always cutting-edge and the training of its highly professional team.

growth

The company’s production unit works for 75% with the foreign market. Export has become the protagonist of the company’s activity, a business that company management cultivates directly and with agents in different parts of the world so that the customer is always supported in their business journey. The company is present with its products all over the world and is constantly expanding.